Here's the cockpit interior showing the mast in the mast step and the curved carlines defining the cockpit opening. The problem is how to make a curved coaming for the cockpit.

The answer is that pile of wood sticks in the back of the cockpit.

The sticks are 3/4" x 2" western red cedar and Alaskan yellow cedar. By laminating them on the carlines a pair of coaming panels which exactly match the curve can be produced. Straight up and down looked boring, so I tilted them backwards to make the boat look fast.

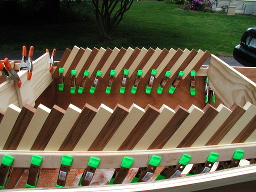

Same setup as the test fit, but first the carlines are covered with clear plastic packing tape to keep the cedar from sticking to them (for now). Plastic is also used to prevent drips from falling into the cockpit (a drip caught is a drip not needing to be sanded).

Each cedar strip is brushed with thickened epoxy before it is placed against the next one. The whole assembly is allowed 24 hours to sit and cure.

2 coaming side panels with curves that exactly match the carlines, all ready for sanding, cutting and glassing. And a mast step with a Hungarian 1-forint coin epoxied into it. That means that the boat is worth at least 1/2 US penny.

In the meantime, a plain pine hatch coaming was made up. There were no fancy curves to follow that required lamination and striped lamination on this coaming as well would have been visually too busy. The bow will get its own color accent, just not in the form of a fancy coaming.

Structurally, the hatch coaming adds a great deal of strength and stiffness to the boat. It helps resist longitudinal flexing and lateral compression. In addtition, it greatly stiffens the deck.

Here are the cockpit bits getting to know each other. The 2 coaming side panels have been cleaned and trimmed and are ready for glassing. Once they were fitted to the carlines it became obvious that a plain pine back would not do, so a striped cedar back panel was laminated up (flat this time). Some friends called this the Max Headroom coaming. I have a new set of friends now. Just kidding. Really.

The front of the coaming is plain pine, to make the visual transition to the simpler front of the boat. Also in place is the mast partner and some leftover mast stock being used as a stand-in for the main mast (which is visible on the wall in front of the boat).

Everything seems to fit and it's time to move onto the deck.